In the bustling world of pet food manufacturing, efficiency, safety, and precision are paramount. From ingredient processing to inspection and packaging, each step demands meticulous attention to detail to ensure the production of high-quality pet food products. One crucial aspect that streamlines these processes is the strategic integration of conveyors. Let’s delve into the various stages of pet food manufacturing and packaging and explore how conveyors play a pivotal role in optimizing these operations.

Ingredient Handling and Processing:

The journey of pet food begins with the careful handling and processing of raw ingredients. Conveyors facilitate the seamless transport of ingredients from storage silos to processing equipment. Whether it’s conveying grains, meats, or vitamins, specialized conveyors ensure efficient and hygienic movement throughout the production facility. Dorner’s AquaPruf conveyors are designed to meet high levels of sanitation and provide easy line changeover while conveying different raw products through the processing stage.

Moreover, adjustable speed and incline features allow manufacturers to maintain precise control over ingredient flow, optimizing mixing and blending processes.

Mixing and Blending:

Consistency is key when it comes to creating nutritious and palatable pet food formulas. Conveyors equipped with weigh scales and mixing capabilities play a vital role in achieving uniform blends of ingredients. These conveyors carefully meter and transport measured quantities of ingredients to mixing equipment, ensuring accurate ratios and minimizing waste. Additionally, integrated automation systems enable real-time monitoring and adjustment of mixing parameters, enhancing product quality and consistency.

Dorner’s Engineered Solutions Group can meet the needs of providing conveyors with integrated technology to provide portion and ratio control to meet specific recipe requirements and prepare food for cooking.

Cooking and Extrusion:

In the case of dry pet food production, cooking and extrusion are critical steps that transform raw ingredients into finished kibble or treats. Conveyors equipped with high-temperature-resistant belts facilitate the smooth transfer of the extruded product through ovens or drying tunnels. These conveyors ensure consistent cooking or drying times, preventing over- or under-processing. Furthermore, adjustable speed controls allow manufacturers to fine-tune processing parameters to achieve desired product characteristics such as texture and moisture content.

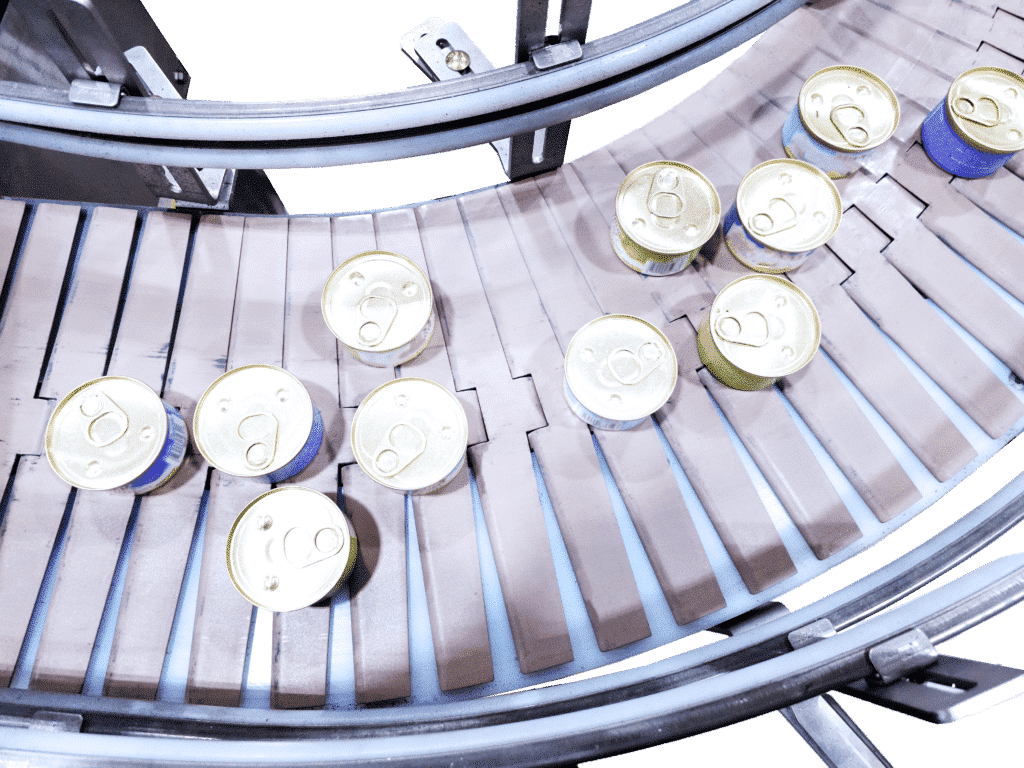

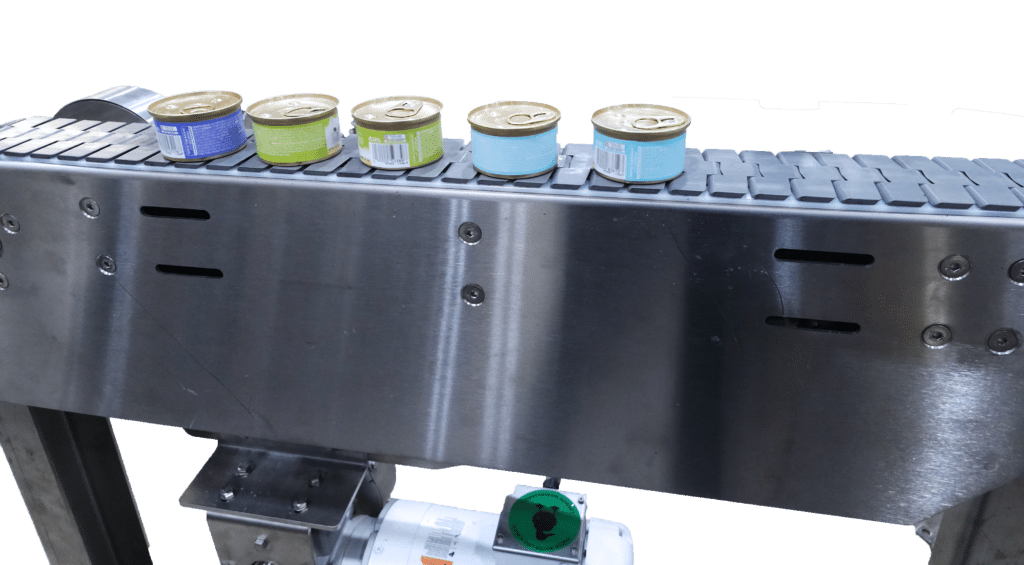

Cooling and Packaging:

Once the pet food products are cooked or extruded, they undergo cooling before packaging. Cooling products is essential due to the potential of product contamination due to the entrapment of elevated temperature products and the risk of harmful bacteria growing. Conveyors equipped with cooling tunnels or ambient air-cooling systems efficiently transport hot or warm products to designated cooling areas. This rapid cooling process helps preserve product integrity and prevents moisture loss. Utilizing conveyance solutions such as Dorner’s sanitary alpine conveyors that can provide a buffer from cooking to packaging, also Garvey’s accumulation systems are perfect for spacing out time Subsequently, conveyors play a crucial role in the packaging phase by transporting cooled products to packaging equipment such as baggers, fillers, and sealers. Integrated conveyor systems ensure smooth product flow, minimizing downtime and optimizing packaging efficiency.

Quality Control and Inspection:

Throughout the manufacturing process, stringent quality control measures are essential to uphold product safety and consistency. Dorner conveyors can be equipped with inspection stations and automated detection systems enable real-time quality assessment. These conveyors facilitate the seamless movement of products past sensors, and backlights, allowing for the detection of contaminants, irregularities, or defects. Timely identification of issues ensures prompt corrective action, safeguarding product quality and consumer trust.

How Conveyors can Help Move Food Processors Forward

Conveyors are indispensable assets in the pet food manufacturing and packaging industry, facilitating efficient, safe, and precise handling of ingredients and finished products. By streamlining processes and enhancing automation, conveyors play a vital role in optimizing production workflows, improving product quality, and meeting the ever-evolving demands of pet food consumers. As the pet food industry continues to innovate and grow, the strategic integration of conveyors will remain integral to driving efficiency and success in manufacturing operations.